About YUDIAN

- Profile -

Yudian Automation Technology Co., Ltd., founded in 1991 with a registered capital of more than $30 million, has specialized in the R&D and production of intelligent temperature controllers for over 30 years. It boasts a self-built, modern factory covering 60,000 ㎡, with an annual production capacity of 10 million units.Currently, Yudian holds the leading global position in terms of industry scale in the temperature controller segment. Our products serve a diverse range of emerging industries, such as photovoltaics, semiconductors, lithium batteries, biotechnology, electromechanical equipment, and advanced materials.

In the field of new energy, Yudian has partnered with leading photovoltaic equipment companies to replace imported temperature controllers. Through technological advancements such as increasing heating rates, reducing overshoot, and shortening process cycles, production efficiency has improved by 8%. This has enhanced equipment utilization and product yield, generating billions in value for customers annually for every 100 million yuan invested in temperature controllers, thereby supporting the domestic photovoltaic industry’s global leadership. In the lithium battery sector, Yudian has served industry leaders for over a decade, significantly advancing cost-saving and energy-efficient processes within the domestic lithium battery industry and enhancing global competitiveness. In the semiconductor industry, where reliability and performance requirements are extremely high, Yudian temperature controllers are widely applied in the production equipment of leading semiconductor companies. They are managed according to the semiconductor industry's stringent quality standards for the supply chain and have consistently met customer demands with outstanding performance.

- Core Technology -

The High Performance Design Not only benefits our customers but also provides benefit to society and the environment

Precise Measurement and Control, Energy Saving for Customers

Yudian instruments are strictly controlled on temperature drift. The measurement temperature drift of AI-7/8 series high performance energy saving instrument Is less than 30ppm/oC, far lower than the market standard. Low temperature drift not only improves the product quality, but also reduces power consumption. For example, where one customer has a heating device that can normally operate under 200 -220oC, the use of low-precision instruments set at 210 oC with the drift of +/- 10 is reluctant to satisfy the production specifications, while YUDIAN instrument can stabilize temperature interval under 201 oC with a drift of +/- 1 oC, reducing the heating temperature from 210 oC to 220 oC resulting in power saving calculated to about 5% of the electric bill.

Using S thermocouple or Pt100 RTD, the measurement will be more stable rather than K or J-type thermocouple is used. Better insulating materials and lower set value (SV) as possible with consideration of manufacturing practice will also save energy effectively

Long Service Life and Low Failure Rate, Less Electronic Garbage

AI series instruments and industrial control modules are designed with a service life of more than 10 years, with 3-year free repair within the warranty period. An easily replicable modular design and one billion times rewritable FRAM extends the service life of the products, effectively reducing the occurrence of electronic garbage, as well as the cost generated by replacing faulty and low performance instruments.

A series of protection functions such as surge protection at power up and 380VAC protection reduces the failure rates occurred. At present, annual return rate inclusive of user installation related issues are lower than 0.5%, reducing both the usage cost and waste due to the destruction of disabled instruments.

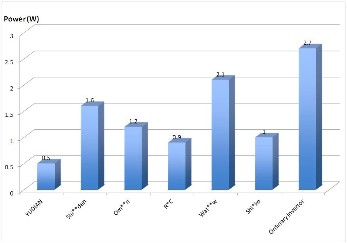

Power Consumption Reduction

The use of high-efficiency switching mode power supply greatly reduces the power consumption, and adaptation of super-luminance LED display reduces power consumption by half. In zero output, the consumption is only around 0.5W, far below the competing products.

Energy saving relay module use high currents only at the beginning of the engaging action, compared with the engaged status being reduced to 50%. This smart technology enables the power consumption to be reduced from 0.2~0.4W to 0.1~0.2W.

Newly-designed G1 module uses 5V/30mA signal to drive SSR while standard G module uses 12V/30mA. G1 can reduce also with 0.1~0.2W the overall power consumption.

In integrated applications, AI instruments can decrease about 2W of power consumption in comparison with other similar products, not only saving energy but also reducing the temperature rise of instruments while increasing the maximum service temperature and reducing the measurement temperature drift. Calculated by service life of 10 years, each instrument can save 175 kilowatt-hour electricity. For a factory with 1000 sets, accumulative saving can be estimated to more than RMB 100,000.

YUDIAN - an emerging automation instrument expert

Yudian Automation Technology Co. Ltd. has been devoting itself to the development and manufacturing of industrial process automation controller instruments since 1991. Through several years of development, YUDIAN has become the number one Chinese intelligent instrument manufacturer, claiming the biggest domestic market share with sales of over 250,000 instruments per year. Our instruments are applied in industries spanning from chemical, petroleum, metallurgy, to pharmaceutical, food and beverage, and academic laboratories. Our products have established the status of high quality and reliable instruments.

Headquartered in Hong Kong, Yudian has established subsidiary companies and branches in North America and Oceania. Now our products have been sold in Hong Kong, India, Australia, New Zealand, America, Southeast Asia and Europe, and are highly ranked by our customers. Yudian has constructed a 10,000m2new-type factory building in the Xiamen Hi-tech industrial develop-ment zone. With multiple modern production and test equipments including full automatic computer placement machines, lead-free dual crest welders, infrared reflow welders, high temperature and high-voltage aging room, electromagnetic compatibility testing and equipment humiture environment test laboratory, Yudian can manufacture automation products at the highest quality with the highest precision and reliability.

Main Products

- AI Series of Intelligent Industrial / Temperature Controllers

- Multi-channel Indicating / Alarming Instruments

- Flow Totalizers

- Voltage/Current/Power Meter

- Paperless Recorders

- D5/E5 series rail mounting intelligent module (including single channel / dual-channel temperature transmitter, switching value and analog input /output module, four-channel PID temperature control module, AI PID control module and flow totalizers module)

- Three-phase thyristor phase-shifting trigger

Certification

- Compliant to IEC 61010-1:2010, Safety requirements for electrical equipment for measurement, contro, and laboratory use.

- Standard Number: UL 61010-1/CAN/CSA-C22.2 No. 61010-1

- Achieved certification of CE, IS09002, ISO 9001 - 2008, ISO 14000:2004 and CQC. UL certification in process.

- Application of environment friendly lead-free welding technology since 2006, satisfying European RoHS Standard (RoHS Directive 2002/95/EC).

- Offers 36 months of product warranty

- Achieved a stable overall product return ratio less than 0.5% including damage due to user's misoperation.

History

|

1991

|

Yudian Automation Technology Company was founded.

|

|

1994

|

A technology breakthrough in the Chinese instrument industry---- AI series Industrial Controllers were first launched. These intelligent controllers were programmable with multiple inputs and

equipped with auto-tuning and self-learning artificial intelligence algorithm.

|

|

1996

|

Yudian was the first company in the world to develop and release modular controllers with artificial intelligence, making a revolutionary breakthrough in global instrumentation.

|

|

1998

|

Achieved registration to ISO 9002 quality certification.

|

|

2000

|

Pioneered and adopted SMT production technology.

|

|

2001

|

Achieved registration to quality certifications of CE, CQC, ISO 9001-2000 version.

|

|

2004

|

Yudian was first to achieve ISO 14000 certification in the China instrument industry. In the meantime, Yudian, with advanced technologies and a reputable brand image, won the investment from

Hong Kong, and restructured itself to a Sino-foreign contractual joint venture with total investment of RMB 50 million. It became the number one Chinese instrument manufacturer with the largest

market share and the strongest competence in China.

|

|

2006

|

The new Yudian Building with 10,000 square meters of manufacturing space was put in use, providing the production ability of 1 million instruments per year.

|

|

2007

|

2057C/G digital paperless recorder, AI-1000C color paperless recorder, and AI-5600 handheld high precision Thermometer were launched.

|

|

2008

|

New generation AI V8.0 series instruments were released with 2 individual PID parameters, which apply heating/cooling in the same process. Meanwhile, Solid-state Relays and AI-5500 handheld

thermometer were launched.

|

|

2010

|

New industrial monitoring and controlling system, featuring true-colored HMI and conventional instruments was launched. It benefits from user-friendly touch screen interface and reliability and

strong anti-interference of instruments.

|

|

2011

|

Ultra high precision Process controller AIJ is launched. With 24-bit A/D, 5-digit display, accuracy up to 0.05%FS, it is suitable for university research, metrology and precise

temperature/process control.

|

|

2012

|

Adhering to the virtue of “Never-ending Improvement, Pursuit in Perfection”, YUDIAN continuously innovates and seeks breakthrough, maintaining the quality and technology in energy saving and

efficiency. The 4-channel PID temperature controller (AI-7048D5) was entitled one of the “National New Key Products” by the Ministry of Science and Technology and acquired American UL

compliance.

|

|

2013

|

High precision energy saving industrial-grade controller AI-733K9 succeeded to merge controller feature with 3-phase thyristor trigger, providing competitive price-to-performance ratio. In 2013,

it was entitled one of the “National New Key Products” by the Ministry of Science and Technology.

|

|

2014

|

Launching AI-3700 series, 7-inch touch screen intelligent temperature controller/regulator. Graphical user interface (GUI) was user friendly comparing to traditional tedious key

operations.

|

|

2015

|

Based on AI-3700 series, more variety of 5-inch and 9-inch touch screen size are available as AI-3500/3900 series, expanding touch operation from controller/regulator to HMI interface and

paperless recorder.

|

|

2016

|

Launching cloud/mobile app remote controlled-enabled touch HMI, paperless recorder and controller/regulator. Rail mounted designed paperless recorder has also been launched apart from

conventional panel mount.

|

|

2016

|

Launching cloud/mobile app remote controlled-enabled touch HMI, paperless recorder and controller/regulator. Rail mounted designed paperless recorder has also been launched apart from conventional panel mount. |

|

2021

|

The Yudian Temperature Control Technology Industrial Park, covering a construction area of 50,000 m2, has officially commenced construction. The domestic replacement of key components in our products has achieved breakthroughs, and we have independently developed a core chip specifically for temperature controllers. This has significantly enhanced the reliability and interference resistance of our products. Additionally, we launched the AI-8 series temperature controllers, which were recognized as being at the “international advanced level” in 2022. |

|

2022

|

Breakthroughs in new technologies such as cascade temperature control algorithms, achieving technological superiority over imported products in the high-end temperature controller field and beginning large-scale replacement of imports in the photovoltaic industry. |

|

2024

|

The Shenzhen Technical Service Center, with a construction area of 4,000 m2, has been established to provide more comprehensive technical support to clients. It has been recognized as a national-level Specialized, Refined, Featured, and Original “Little Giant” enterprise. |

|

2025

|

Batch entry into temperature control for core components of semiconductor equipment. Breakthrough in high-temperature resistance technology for temperature controllers, with a maximum resistance of 150°C. Launch of 4~32-loop multifunctional and series multi-loop temperature control modules. Selected as a National Key Specialized, Refined, Distinctive, and Innovative “Little Giant” Enterprise. |